FUSE LINK

A STORY TO TELL

A blown fuse has a story to tell. It is frustrating for linemen to find open cutouts without any sign of problems on the line. A fuse that has been removed from a cutout and visually examined is sometimes classified as a nuisance operation”, when in truth the fuse was operating because there was a fault and the fuse reacted to it. By observing certain characteristics of the LUHFSER fuse links, you will be able to ascertain when the fuse operated and under which current levels.

Construction of a fuse

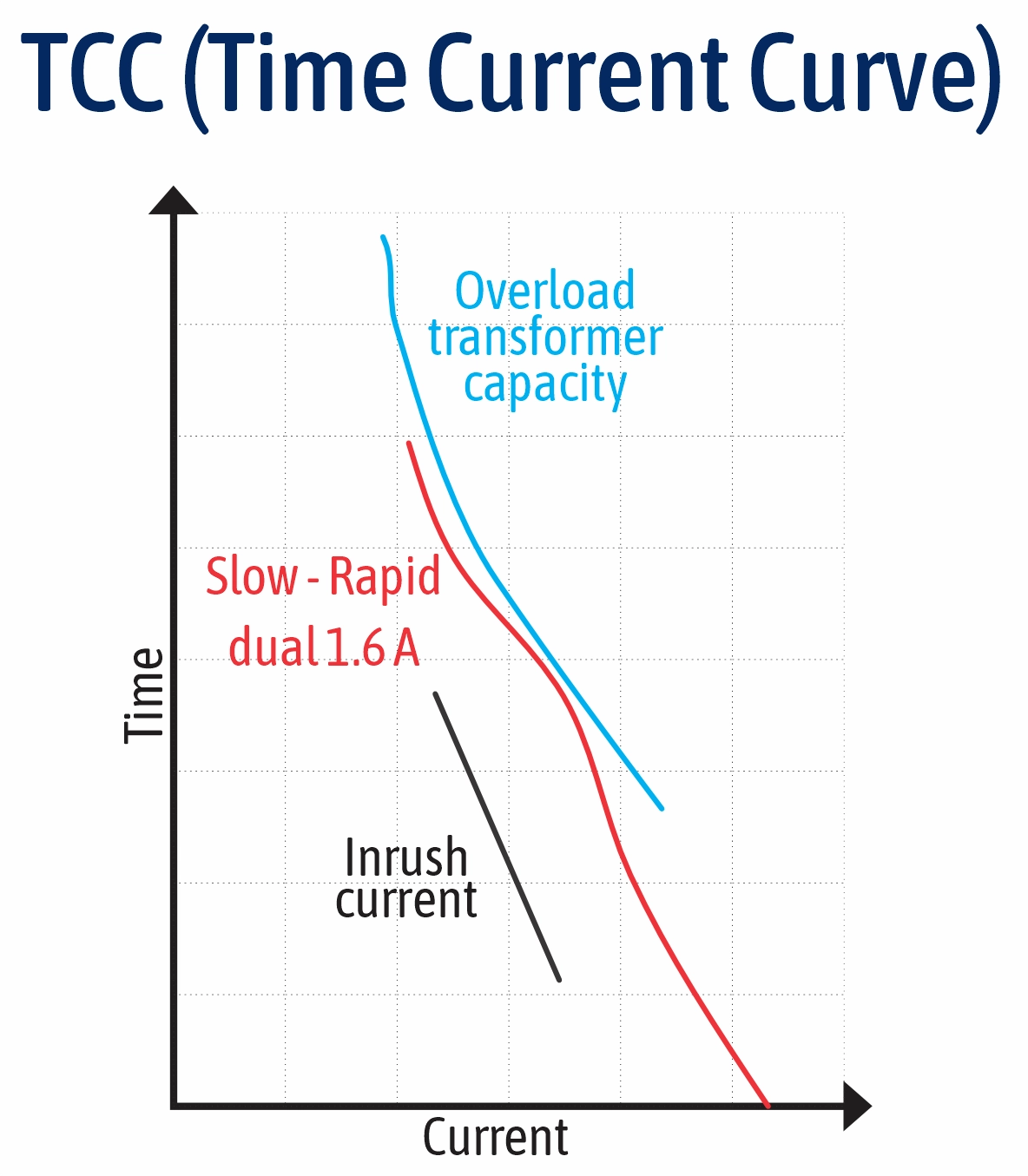

In order to analyze the remains of a fuse it is essential to be familiar with their construction. Different materials such as low melting wires, solder or pressed fuse elements the correct size of the tinned copper cables, coils, and welded joints are all used to control the fuse operation's speed. The performance of different fuse link speeds are illustrated in the time-current curves provided below.

NOMINAL CURRENT:

6H, 6K,6M, 6T, 7VS & 6.3SR

LUHFSER EXPULSION FUSE LINK SPEED CHART.

BRAND

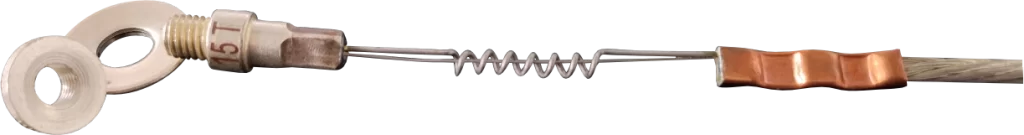

Construction of type-T fuses

The 1,2 and 3 amp fuses have a Fe – Cr - Al fuse element which serves as both fuse element and tensor wire. Fuses ranging from 6 to 100 amp., have a stainless-steel wire, which mainly serves to absorb the mechanical tension upon closing, electric current mainly flows through a parallel tin or silver alloy wire, which is pressed and welded in both the head and the copper ferrule. 140 and 200 amps fuses have a tin plate that is welded to the head and the copper ferrule. There is also an option for silver alloy wire pressed fuse links for those ratings.

T Fuse link 80 Amp.

T Fuse link 15 Amp.

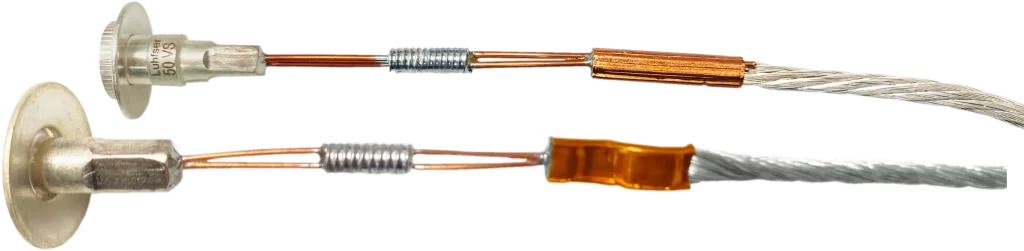

Construction of type-K fuses

The construction of 1-100 amps fuses is the same as for type T; fuses of 140 and 200 amps have a silver-copper alloy wire, which is pressed in both the head and the copper ferrule.

K Fuse link 80 Amp.

K Fuse link 30 Amp.

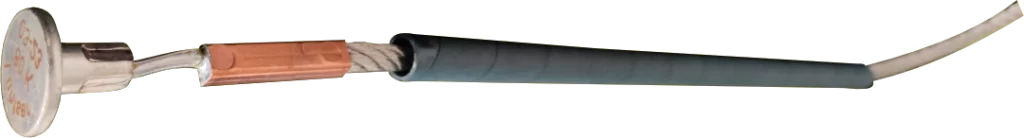

Construction of SR (SLOW - RAPID) fuses

The SLOW-RAPID fuse has two sections. The slow section has a temperature special alloy in form of a coil pressed into a tin solder juncture. The rapid section has a stainless steel tension wire in parallel to a copper wire, similar to the type H fuse link. This second section is press onto a copper ferrule that is held together with the slow section, by the use of a juncture. Sections rapid and slow are solder together.

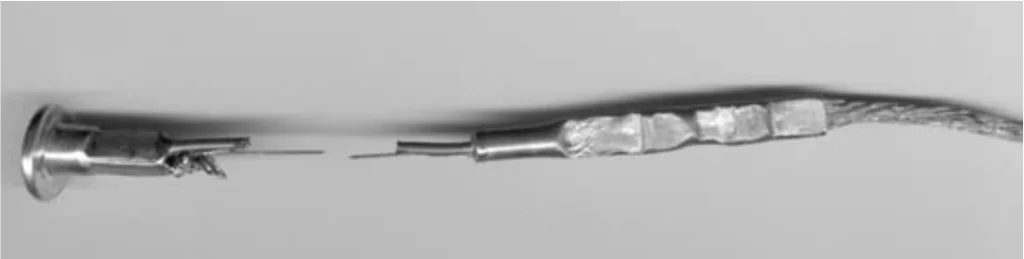

SR Fuse link 10 Amp.

Construction of type-VS fuses

The VS Fuse, like the SLOW-RAPID fuse, has 2 sections, The slow section has 2 parallel copper-nickel alloy wire, pressed into the head. The rapid section, as the slow one, has 2 parallel copper - nickel alloy wires, pressed into the copper ferrule. Both sections are solder together.

VS Fuse link 50 Amp.

Operation of a fuse.

High fault current, 1000 amp. and higher, is asier to recognize. The auxiliary tube is destroyed, and the fuse element wire is consumed. On the other hand, when the faults are in the 500 to 1,000 amp range, the auxiliary tube is burned but preserves most of its appearance. In these cases, most of the fuse element wires are consumed depending on the size of the fuse. Unlike high fault currents, overload or low fault currents are hard to diagnose, since the damage is not noticeable. In a low fault current, the auxiliary tube is not damaged, and the fuse element even though has melted is practically intact. Knowing how a fuse element looks after a fault has occurred, makes it easier to recognize which type of fault just happened. These characteristics vary depending on the type of fuse.

Low fault currents type T fuses.

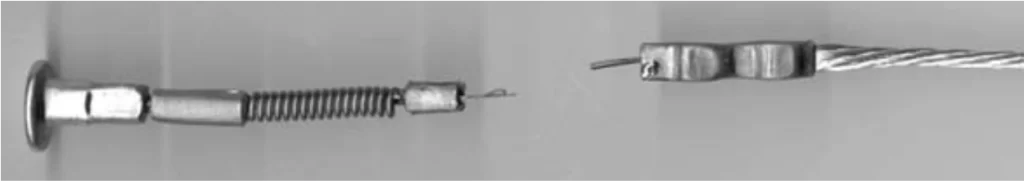

1 to 100 amp. type-T fuses which have operated with low fault currents or overloaded, will show unbroken auxiliary tubes. The tin fuse wire will melt somewhere between the head point and the copper ferrule, transferring all the current to the tension wire, which in turn will be melted near the middle. After the interruption, the tin fuse element wire will keep its original smooth surface.

T Fuse link 100 Amp.

T Fuse link 12 Amp.

↑ The copper ferrule pressed parts will remain intact ↑

Type-T blown fuse.

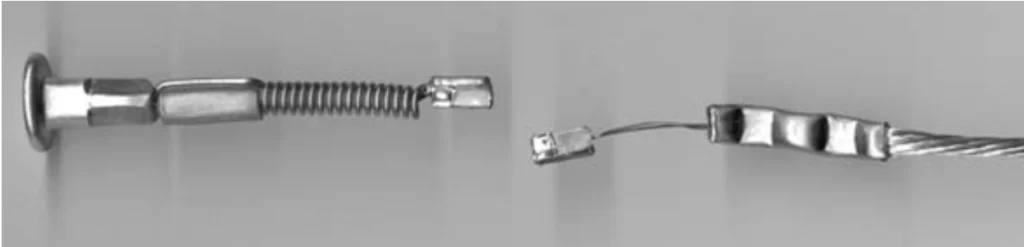

1 to 100 amp. type T fuses which have been electrically short circuited, will show signs of a mayor blow. The copper ferrule, rugged and its lower section will be broken. The tension wire will also be blown from the head point or the copper ferrule, recognizable by the bent end of the wire, or it will vaporize on either end. The amount of tension wire and fuse element wires consumed will be proportional to the fault current and the nominal current ratio. A fault that is 15 times the nominal current will consume more tension wire and fuse element wire than a fault that is 3 times the nominal current.

Fault current 15 times the nominal current

Fault current 3 times the nominal current

Low fault currents type K fuses.

Same as with type-T, the tension wire and the fuse element melt somewhere between the head point and the copper ferrule would be unaffected.

Type-K blown fuse.

1-to-100-amp. type-K fuses that have been short circuited and blown will show similar results to those of type-T

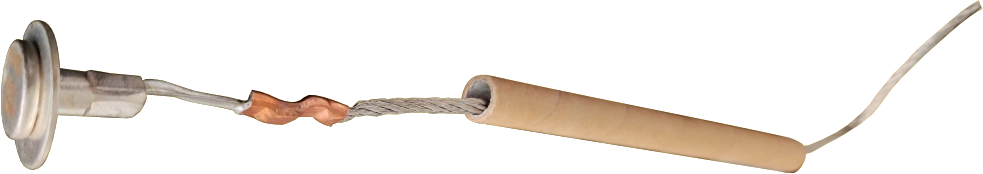

Low fault current SR fuses.

SLOW-RAPID fuses have two sections that can operate with a 500 amp or lower current. The RAPID section is similar to that of a type-H fuse link, as the fuse operates when the fault current is below 4 seconds of the minimum melting curve

A SLOW-RAPID fuse operating in the slow section, with low fault currents or overloads will transmit enough heat to the ceramic components, and this in turn to the joint, causing the separation of the juncture (solder joint).

The remains would look like this. Operated with 5.8 amp. in a SR-FUSE 1.6 Amp.

SR fuse blown.

With this type of fault, the tension wire and the fuse element would be melted somewhere between the joint and the copper ferrule

The remains would look like this. Operated with 110 amp. in a SR-FUSE 1.6 Amp.

Low fault current VS- type fuses

In VS-type fuses, when operating with low fault currents or overloads it will transmit enough heat through the fuse wires to the welded joint to cause the melting of the solder and cause the opening of the circuit

The remains would look like this. Operated with 17.5 amp. in a VS-FUSE 7 Amp.

Type VS blown fuse.

When a VS-fuse is short circuited, the fuse elements will blow and break right in the middle.

The remains would look like this. Operated with 390 amp. in a VS-FUSE 7 Amp.

SUMMARY

Knowing all of this, you can check the characteristics of an overload type against a short circuit type of fault interruption. When the auxiliary tube is not burned meaning the type of fault was an OVERLOAD, look for the following signs:

- Type T - K: fuse link and tension wires are melted somewhere in the middle, the copper ferrule is undamaged, and the surface of the fuse element remains smooth

- Type SLOW-RAPID: parts remain undamaged, the juncture (solder joint) appears detached and the fast section with the conventional wires remain intact.

- Type VS parts remain undamaged and the top wires detach from the coil.

Learn more about our fuse links

Eléctricos Internacional S.A.S., with 40 years of experience in the manufacture and commercialization of products used in electrical distribution, has taken up the work of Dr. Guy Combeau and his wife Blanca de Combeau, becoming the standard bearer for the diffusion, research and improvement of their products. Thanks to the experience acquired and the research carried out in the laboratory, they have realized that there is no guide and reference material that can be used for the proper handling of expulsion fuses.